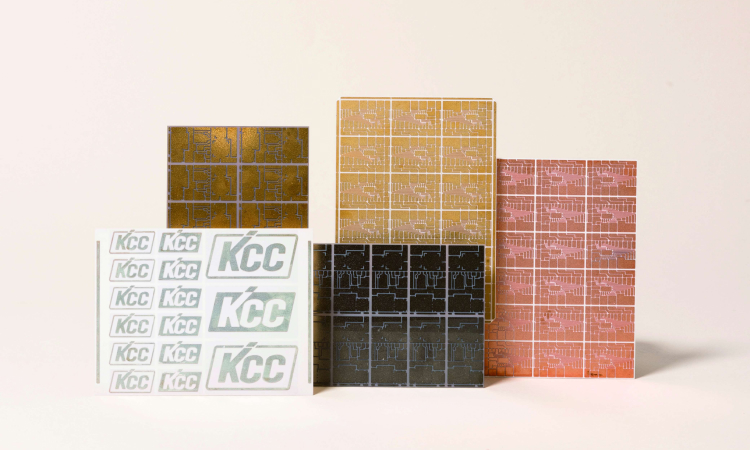

Advanced Materials

KCC's Advanced Materials are the solutions for the future.

- Metallized Ceramics with excellent electrical insulation and hermetic sealing

- Metalized Ceramics are a core material used in electric/electronic insulation components, whereby ceramic and metal are bonded by coating the metal onto the surface of alumina ceramic (AI₂O₃) to secure air-tightness.

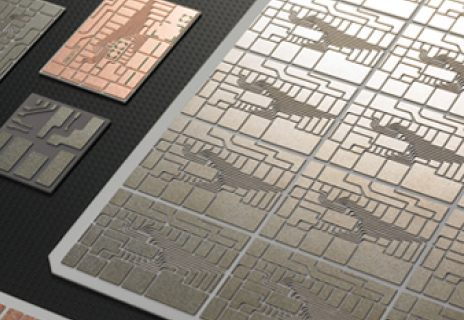

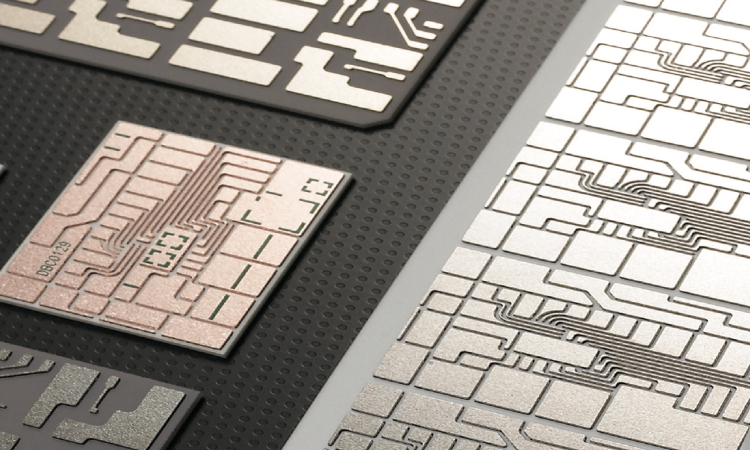

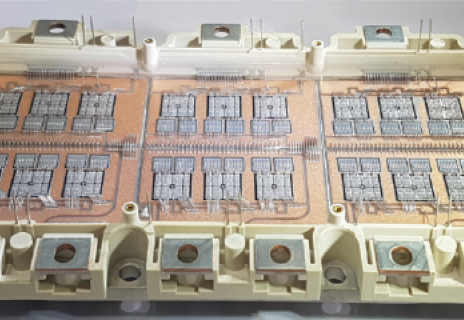

- Ceramic Substrates are the core heat dissipation materials of power modules.

- By bonding copper onto the ceramic board, Ceramic Substrates are used as power module substrates. Since copper can be bonded onto various types of ceramics to provide strength and thermal conductivity to varied levels of customers' needs, Ceramic Substrates are essential materials for power modules in automotive, industrial, and home appliances.

(Alumina Metalizing)

KCC establishes an efficient, automated process by applying the cutting-edge equipment and technology, and produces Metalized Ceramics based on the integrated quality management system. We develop integrated module products using our core technologies, metalizing and brazing technologies, and supplying parts by integrating ceramic and various metal parts to help customers shorten processes and reduce costs.

Moreover, we supply the best assembly products from state-of-the-art high vacuum brazing facilities, continuous brazing facilities, and in-house processing facilities for various metal parts. Based on the ceramic substrate molding (tape casting) technology, we produce ceramic substrate products, the core materials of power modules, and DCB and AMB substrates made from Alumina (AI₂O₃), Aluminum Nitride (AIN), and Silicon Nitride (Si3N5). We have a variety of ceramic substrate technologies. In particular, we have a vertically integrated process from raw materials to finished products, leading the market for electrical/electronic ceramic materials with both superior quality and competitiveness

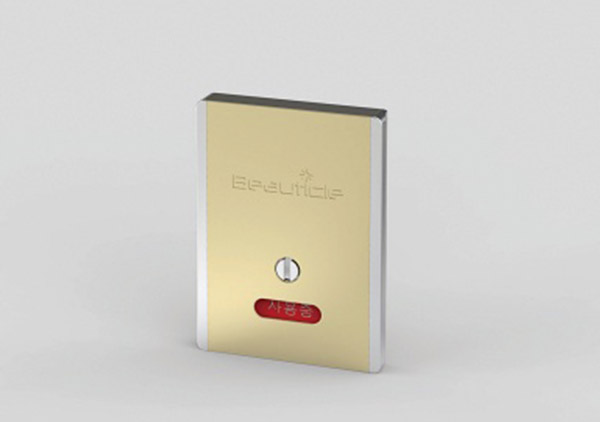

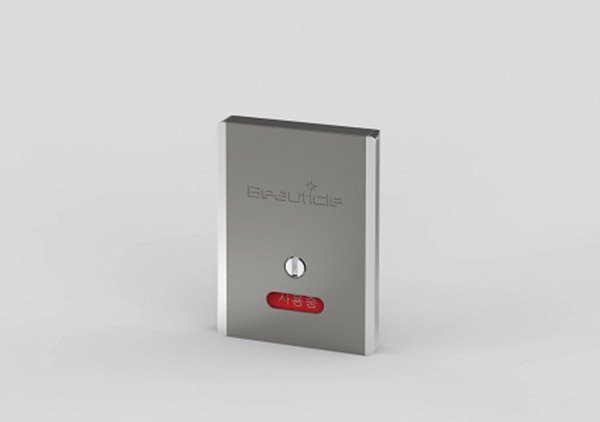

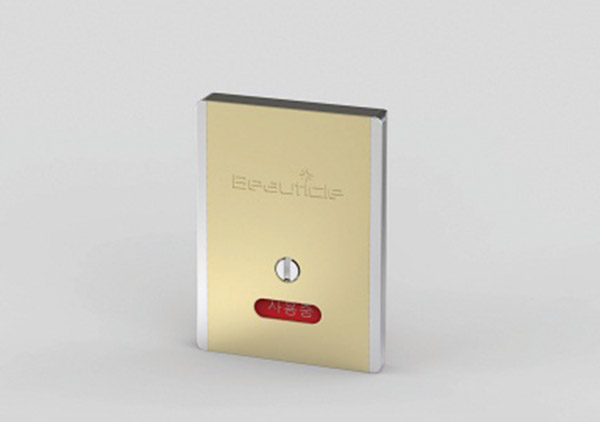

Ceramic for vacuum interrupter (VI)

VI (Vacuum Interrupter) is a component applied to the breaking part of a vacuum circuit breaker, a switch cutting off circuits when abnormal currents including high voltage overcurrent or short circuit occur in power plants, transmission and substation facilities such as chemical, steel, plants, and construction facilities. It is an essential part for power supply. Vacuum is used as an insulating medium, and a ceramic tube with excellent bonding performance, tissue density, and vacuum tightness is applied as a housing material.

KCC is the only ceramic manufacturer for vacuum circuit breakers in Korea and manufactures ceramic insulators using AM (Alumina Metalizing) technology. In particular, as the application of SF6-free vacuum circuit breakers not using SF6 gas which is the main culprit of the global warming increases, we keep pace with the market demand for environmentally friendly products. It is in the spotlight as a key component of the future electric power business considering eco-friendliness and various customers' needs.

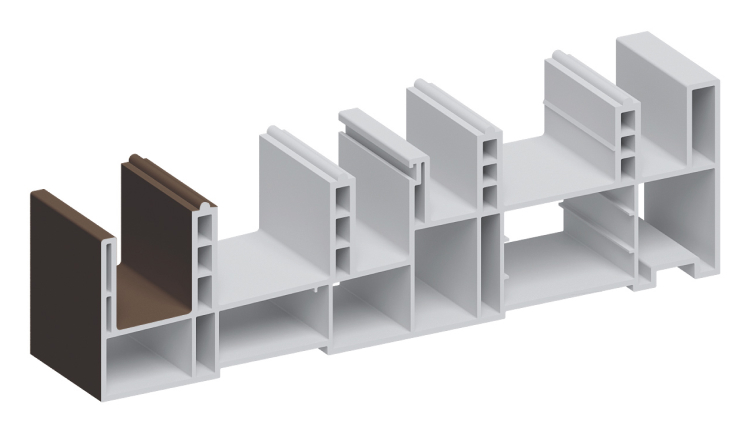

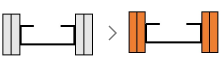

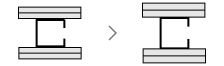

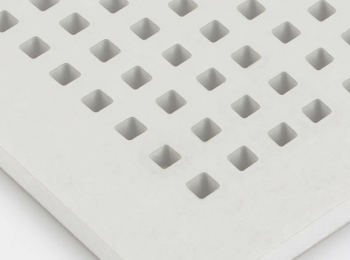

Direct Copper Bonding (DCB) boards used as a power module board

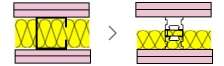

A power module is a power semiconductor module converting the form of electricity (direct current, alternating current), voltage, and current into an appropriate form and size required by the system. It is mainly applied to automotive, industrial, and home appliances. Since power modules are high-power, ceramics with excellent heat dissipation characteristics and reliability are used as the substrates, and various requirements are considered by each industry.

KCC uses DCB (Direct Copper Bonding) and AMB (Active Metal Brazing) bonding technologies to bond copper to various ceramics including (AI₂O₃), ZTA, AlN, H-AlN, and Si3N5 to create products with strength and heat dissipation performance meeting customers' needs.

Application example

[㎡]

[㎡]